Copyright 2023 Robert Clark

(patents pending)

(Appended at the bottom below are additional suggestions for combining graphene/carbon nanotubes.)

Carbon nanotubes were created in the early 1990's. Experiments on them revealed extraordinary strength in the range of 1,000 times higher tensile strength per weight than standard grade steel plate and 100 times higher tensile strength per weight than the strongest steel wires available.

Graphene which can be regarded as carbon nanotubes flattened out were discovered about a decade later. Experiments confirmed they had comparable strength to carbon nanotubes.

The only problem towards making them common industrial materials is that they have only been available in small sizes, at microns to a few millimeters in size.

This is a proposal for constructing larger size graphene and carbon nanotubes.

I.)Creating Large Graphene Sheets.

Recent research has produced hybrids of graphene and carbon nanotubes:

James’ bond: A graphene/nanotube hybrid

Rice University’s James Tour Group creates single-surface material for energy storage, electronics

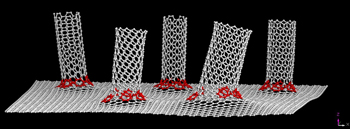

Seven-atom rings (in red) at the transition from graphene to nanotube make this new hybrid material a seamless conductor. The hybrid may be the best electrode interface material possible for many energy storage and electronics applications. Image by Yang Yang/Yakobson Group

Nanotubes are grown from graphene to create nanoscale odako, so named for the giant Japanese kites they resemble. Image courtesy of the Tour Group

https://news2.rice.edu/2012/11/27/james-bond-a-graphenenanotube-hybrid-2/

The researchers were able to attach carbon nanotubes to graphene sheets.

Several teams have been able to create such hybrids, [1], [2], [3], [4], [5]. Usually, these are formed by placing nanotubes onto graphene. However, one team was able to place graphene onto nanotube surfaces, [6].

Repeating such hybrids into multiple layers, the strength and electrical properties of graphene and carbon nanotubes can be extended into 3-dimensions, [7], [8], [9], [10]:

Hybrid Structures of Graphene and Nanotubes Exhibit Unique Mechanical Properties

By Stuart MilneSep 15 2015

By Stuart MilneSep 15 2015

However, other research had shown it is possible to "unzip" carbon nanotubes to turn them into graphene sheets:

Unzipping Carbon Nanotubes: A Peeling Method for the Formation of Graphene Nanoribbons†

https://onlinelibrary.wiley.com/doi/full/10.1002/anie.200902534?saml_referrer

Several different methods have been found for accomplishing the unzipping, [11], [12], [13]. However, for my purposes the unzipping has to be targeted, as well as being able to cut the graphene at a targeted location in the graphene/nanotube hybrid. I therefore suggest using electron beams or x-ray beams to cut the graphene/carbon nanotubes at the specified locations:

The idea would be to slice the graphene-nanotube along the lines shown then open up the material flat, to get a larger single sheet of graphene. Then the process would be repeated to attach further nanotubes, slice them open as well and open them up to get a larger sheet of graphene to make a graphene sheet arbitrarily large.

II.)Creating long nanotubes.

That's for creating arbitrarily large graphene. How about for arbitrarily long nanotubes? First the large graphene sheets would be created. Then methods for rolling up the graphene into carbon nanotubes would be used. Theoretical simulations had shown this possible, [14]:

Graphene Nanoribbons Zip Up

February 23, 2012• Physics 5, s29

Nanoscale planar materials such as graphene could be twisted to fabricate tubular objects.

O. Kit, Phys. Rev. B (2012)

https://physics.aps.org/articles/v5/s29

And this has been experimentally confirmed:

REFERENCES.

Rahul Rao, Gugang Chen, Leela Mohana Reddy Arava, Kaushik Kalaga, Masahiro Ishigami, Tony F. Heinz, Pulickel M. Ajayan & Avetik R. Harutyunyan

Scientific Reports volume 3, Article number: 1891 (2013)

https://www.nature.com/articles/srep01891

2.)Growing Carbon Nanotubes from Both Sides of Graphene.

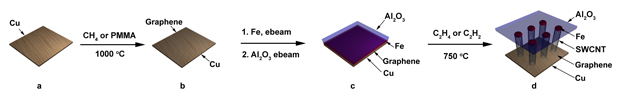

Jinlong Jiang*‡§, Yilun Li‡, Caitian Gao‡#, Nam Dong Kim‡, Xiujun Fan‡, Gunuk Wang‡, Zhiwei Peng‡, Robert H. Hauge‡⊥, and James M. Tour*‡⊥||

ACS Appl. Mater. Interfaces 2016, 8, 11, 7356–7362

Publication Date:February 23, 2016

https://doi.org/10.1021/acsami.5b12254

3.)A Three-Dimensional Carbon Nanotube/Graphene Sandwich and Its Application as Electrode in Supercapacitors.

Zhuangjun Fan, Jun Yan, Linjie Zhi, Qiang Zhang, Tong Wei, Jing Feng, Milin Zhang, Weizhong Qian, Fei Wei

First published: 20 August 2010

https://doi.org/10.1002/adma.201001029

Open Access

Published: 11 March 2019

High-Electrical-Conductivity Multilayer Graphene Formed by Layer Exchange with Controlled Thickness and Interlayer.

Hiromasa Murata, Yoshiki Nakajima, Noriyuki Saitoh, Noriko Yoshizawa, Takashi Suemasu & Kaoru Toko

Scientific Reports volume 9, Article number: 4068 (2019)

https://www.nature.com/articles/s41598-019-40547-0

Nanotube 'rebar' makes graphene twice as tough

by Mike Williams, Rice University

https://phys.org/news/2018-08-nanotube-rebar-graphene-tough.html

Zheng Yan†, Zhiwei Peng†, Gilberto Casillas∥, Jian Lin‡§, Changsheng Xiang†, Haiqing Zhou†, Yang Yang†‡, Gedeng Ruan†, Abdul-Rahman O. Raji†, Errol L. G. Samuel†, Robert H. Hauge†‡⊥, Miguel Jose Yacaman∥, and James M. Tour†‡§*

ACS Nano 2014, 8, 5, 5061–5068

Publication Date:April 2, 2014

https://doi.org/10.1021/nn501132n

9.)Pillared graphene gains strength

MIKE WILLIAMS – SEPTEMBER 14, 2015

POSTED IN: CURRENT NEWS

https://news2.rice.edu/2015/09/14/pillared-graphene-gains-strength/

DEXTER JOHNSON

09 APR 2014

https://spectrum.ieee.org/graphene-and-carbon-nanotubes-two-great-materials-even-better-together

11.)Published: 24 April 2009

Graphene nanoribbons

Unzipping nanotubes

Gavin Armstrong

Nature Chemistry (2009)

Two methods for producing graphene nanoribbons by unzipping carbon nanotubes have been developed.

https://www.nature.com/articles/nchem.236

Longitudinal unzipping of carbon nanotubes to form graphene nanoribbons

Dmitry V. Kosynkin, Amanda L. Higginbotham, Alexander Sinitskii, Jay R. Lomeda, Ayrat Dimiev, B. Katherine Price & James M. Tour

Nature volume 458, pages872–876 (2009)

https://www.nature.com/articles/nature07872

13.)Unzipping of Single-Walled Carbon Nanotube for the Development of Electrocatalytically Active Hybrid Catalyst of Graphitic Carbon and Pd Nanoparticles.

Siniya Mondal, Sourov Ghosh, and C. Retna Raj

ACS Omega 2018, 3, 1, 622–630

Publication Date:January 19, 2018

https://doi.org/10.1021/acsomega.7b01913

O. O. Kit, T. Tallinen, L. Mahadevan, J. Timonen, and P. Koskinen

Phys. Rev. B 85, 085428 – Published 23 February 2012

https://journals.aps.org/prb/abstract/10.1103/PhysRevB.85.085428

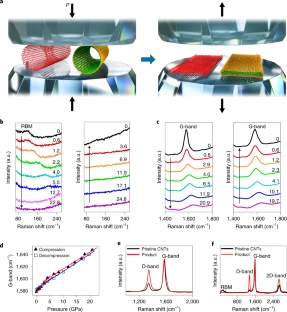

UPDATE: 2/14/2023: Squashed together carbon nanotubes and graphene sheets.

EDITORIAL FEATURE

New Research Narrows the Gap for Graphene Nanoribbon Applications

Cvetelin Vasilev, Ph.D.

https://www.azonano.com/article.aspx?ArticleID=5868

Published: 06 September 2021

Sub-10-nm graphene nanoribbons with atomically smooth edges from squashed carbon nanotubes.

Changxin Chen, Yu Lin, Wu Zhou, Ming Gong, Zhuoyang He, Fangyuan Shi, Xinyue Li, Justin Zachary Wu, Kai Tak Lam, Jian Nong Wang, Fan Yang, Qiaoshi Zeng, Jing Guo, Wenpei Gao, Jian-Min Zuo, Jie Liu, Guosong Hong, Alexander L. Antaris, Meng-Chang Lin, Wendy L. Mao & Hongjie Dai

Nature Electronics volume 4, pages 653–663 (2021)

https://www.nature.com/articles/s41928-021-00633-6 (behind paywall)

Free PDF: http://sscms.hpstar.ac.cn/hpstar/upload/files/2021/9/76740ddde9b92399.pdf

Then the proposal is to use graphene sheets and/or carbon nanotubes laid one on top of another but with only for a short overlap distance compared to their lengths. The test is to see if the high pressure compression can induce the carbon-carbon bonds of graphene/nanotubes between the layers of the graphene/nanotubes. Previous work with graphene and nanotubes have been able to induce much weaker van der Waals bonds between the carbon atoms. These do not have the same strength as the carbon-carbon covalent bonds that prevail in graphene and carbon nanotubes.

The purpose of the short overlap distance compared to their lengths is that likely there will be a combination of the stronger carbon-carbon bonds and van der Waals bonds between the layers. You might then need several layers to make the equivalent cross-sectional strength of a single graphene/nanotube layer. However, by making this portion of the composite small compared to the rest of the graphene/nanotubes the overall strength to weight ratio will be close to that of the pure graphene or carbon nanotubes.

No comments:

Post a Comment