SpaceX is having difficulty creating an effective thermal protection system. I think they should reconsider using wings for return. For instance using sufficiently lightweight wings, it may be possible no thermal protection would be needed at all.

This is the thesis put forward here. The idea behind it was an article that suggested with sufficiently low wing loading, weight per wing area, an orbital stage might need no thermal protection at all on reentry:

Wings in space.

by James C. McLane III

Monday, July 11, 2011

Wing loading (the vehicle’s weight divided by its wing surface area) is a prime parameter affecting flight. The antique aluminum Douglas DC-3 airliner had a big wing with a low loading of about 25 psf (pounds per square foot of wing surface). At the other end of the spectrum, the Space Shuttle orbiter has a high wing loading of about 120 psf. This loading, combined with an inefficient delta-shaped wing, makes the orbiter glide like a brick. A little Cessna 152 private plane features a wing loading of about 11 psf and modern gliders operate down around 7 psf. A space plane with huge lifting surfaces and a very low wing loading might not require any external thermal insulation at all. Building a space plane with a wing loading of, say, 10 psf should not be an impossible proposition. Perhaps some day it will be done.

http://www.thespacereview.com/article/1880/1

I discussed the possibility here:

Reentry of orbital stages without thermal protection? UPDATE: 7/1/2019

https://exoscientist.blogspot.com/2019/06/reentry-of-orbital-stages-without.html

The proposer of this idea was the legendary spacecraft designer Maxime Faget, who was the chief designer of the Mercury capsule, the first U.S. manned space capsule. Then on that basis alone the possibility should be given serious consideration.

The parameter though used to measure the capability of a particular shape to slow down descent is not wing loading, weight divided by wing area, but the ballistic coefficient, (mass)/(drag coefficient*drag area), β = m/CDA, given in metric units, where the drag area is by cross-section. This takes into account the fact different shapes are more effective in slowing down the spacecraft by including the coefficient of drag CD as well as being more general than just looking at wings for the decelerator.

A couple of ways being investigated to get a lightweight decelerator are by using a inflatable and by using a foldable heat shield.

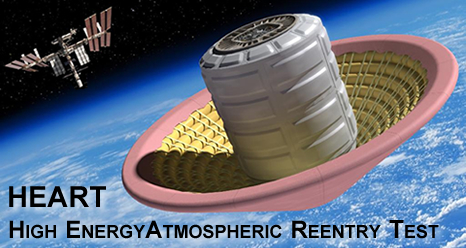

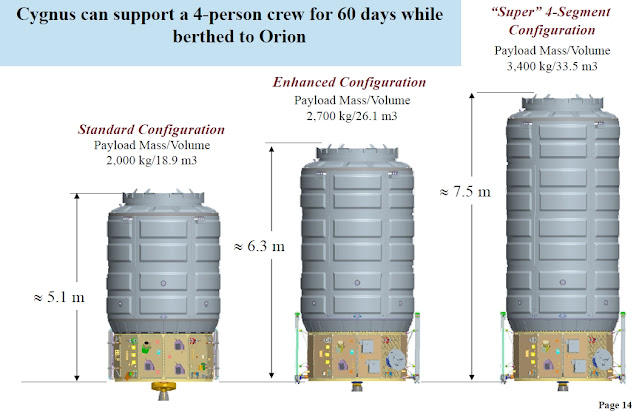

There are several variations of the inflatable heat shield idea, sometimes called a ‘ballute’. The most researched one is a conical inflatable heat shield. It’s being investigated for example as a heat shield to make the Cygnus cargo capsule reusable:

Here’s a research article on it:

HEART FLIGHT TEST OVERVIEW

9th INTERNATIONAL PLANETARY PROBE WORKSHOP 16-22 JUNE 2012, TOULOUSE

https://websites.isae-supaero.fr/IMG/pdf/137-heart-ippw-9_v04-tpsas.pdf

In this report, the mass used for their analysis is ca. 5,000 kg and the diameter of their conical decelerator is 8.3 meters. There is thermal protection applied but I gather less of it is needed since the conical aeroshell is just made of silicone rubber.

To get the low ballistic coefficient you want to minimize the dry mass of the upper stage or capsule being returned. This is a concept understood by spaceflight engineers: extra mass added to an upper stage subtracts directly from payload. So spaceflight engineers commonly try to minimize this dry mass.

I have discussed before I believe it is a mistake for SpaceX to want to go directly to a fully reusable upper stage. Elon Musk once estimated that an expendable Starship upper stage without fairing could be made at only 40 tons dry mass:

Elon Musk @ElonMusk

Probably no fairing either & just 3 Raptor Vacuum engines. Mass ratio of ~30 (1200 tons full, 40 tons empty) with Isp of 380. Then drop a few dozen modified Starlink satellites from empty engine bays with ~1600 Isp, MR 2. Spread out, see what’s there. Not impossible.

https://x.com/elonmusk/status/1111798912141017089?s=61

Now, in their attempts at making it fully reusable the dry mass has ballooned to ca. 160 tons or more. That huge dry mass is the primary reason why they are having difficulty finding effective thermal shielding.

Then in the following I’ll assume SpaceX does go first for an expendable Starship upper stage at ca. 40 tons dry mass. Then when they do proceed to reusability of the upper stage, if it is just ballistic coefficient determining the effectiveness of the heat shield, then for a spacecraft or stage about 9 times heavier than the HEART shield for the Cygnus, say, at 40,000+ kg, then the area needs to be 9 times more, that is, a conical shell about 25 meters in diameter.

BUT, the key questions is how does the mass of the decelerator scale with the size of the reentry spacecraft? In this report the added mass of the inflatable shield is a small proportion of the spacecraft being returned, in the range of 25%. But that is for a returned spacecraft of ca. 5,000 kg dry mass, with decelerator mass of ca. 1,300 kg.The report doesn’t discuss how the mass of the decelerator scales with size. You could make an argument it should scale with the cube of the decelerator diameter. The reason is because of not just the area increasing but the shield thickness also increasing to maintain shield strength. Then for a cone shield of 3 times larger diameter the mass would be 33 = 27 times heavier or 35,000 kg. That is quite larger percentage of the 40,000 kg stage dry mass. It is still much better than the 120+ ton added mass the Starship now has in the attempt to make it reusable.

On the hand, you could make an argument it should scale by the square of the diameter. The reason is you could use multiple copies of the smaller cone shields to cover the entire returning spacecraft. So it would be 32 = 9 times heavier or 9*1,300 = 11,700 kg being added to the dry mass. This would be a more palatable increase, if that is indeed the correct scaling.

This report though doesn’t give the maximum, i.e., stagnation temperature reached so it’s a little difficult to see if steel itself would be able to withstand the heating. It describes using layers of the Nextel thermal blankets so presumably this would also work for the Starship or other stages or capsules with the appropriate size conical shield for the reentry dry mass.

But we can make an estimate of what size wings for the Starship could get similar ballistic coefficient as the inflatable conical shell and therefore existing off-the-shelf Nextel thermal blankets would suffice for the thermal shield.

For the example considered in this report, the dry mass of the returning spacecraft is approx. 5,000 kg and the area on the inflatable is about 56 m2. Then the ratio of mass to area is about 100 kg/m2. But actually the ballistic coefficient also divides this by CD , the coefficient of drag. At hypersonic speeds the drag coefficient of a 55 degree half-angle cone is about 1.5, so the ballistic coefficient is of about 60 kg/m2.

For the expendable Starship at 40 tons, adding on the fairing at ca. 20 tons brings the total mass to ca. 60 tons. At a diameter of 9 meters and length of 50 meters, the cross sectional area is 450 m2. To calculate the ballistic coefficient also need the hypersonic drag coefficient. For a cylinder entering broadside that is about 2. Then the ballistic coefficient is 60,000/(2*450) = 66 kg/m2.

This is close enough for the Starship itself without wings only using existing Nextel thermal blankets to survive reentry for reuse as long as SpaceX starts with the lightweight value of the expendable version.

Another method for lightweight thermal shielding via low ballistic coefficient would use a foldable heat shield. This is the approach investigated by Dr. David Akin, of the University of Maryland, he calls it a ‘parashield’. He described it as used for a lightweight manned space capsule here:

Phoenix: A Low-Cost Commercial Approach to the Crew Exploration Vehicle

Abstract: Since the announcement of President Bush’s Vision for Space Exploration (VSE) in early 2004, the architecture of Project Constellation has been selected. The system will be centered around the Crew Exploration Vehicle (CEV), which has been dubbed by NASA administrator Michael Griffin as “Apollo on steroids”. The CEV is to be launched on a new launch vehicle, derived from existing shuttle technology. The development of this new

spacecraft and launch vehicle is a very costly proposition. An alternate approach is proposed in this study. The Phoenix is a smaller spacecraft designed specifically to be launched on the Falcon 5 vehicle under development by SpaceX. Because the SpaceX vehicle will cost only a fraction of today’s launch costs, the Phoenix is estimated to cost less than half of the price of the CEV. This reusable three person capsule utilizes an innovative re-entry concept, which allows for a cylindrical spacecraft with greater interior volume. This extremely cost-effective spacecraft is an attractive option for fulfilling VSE requirements.

SpaceOps 2010 Conference

25-30 April 2010, Huntsville, Alabama AIAA 2010-1928

Applications of Ultra-Low Ballistic Coefficient Entry Vehicles to Existing and Future Space Missions

David L. Akin∗

Space Systems Laboratory, University of Maryland, College Park, MD 20742

https://spacecraft.ssl.umd.edu/publications/2010/SpaceOps2010ParaShieldx.pdf

The author here uses units of N/m2 which is Pascals instead of kg/m2, perhaps because he wants to use units of pressure and to make an analogy to aircraft design’s “wing loading” units of pounds per unit area. But it is easy to convert to the more common kg/m2 by dividing by 9.81, i.e., approximately by 10.

Here he takes the desired ballistic coefficient as 200 Pa, about 20 kg/m2. This article does give the max stagnation temperature so we can estimate the size of wings needed to reach that ballistic coefficient. Quite notably in this report the peak heating only reaches 800°C. The author notes this is within the temperature range of off-the-shelf Nextel blankets to withstand. But that’s what would be needed for a standard aluminum structure. Stainless steel has a melting point in the range of ca. 1,400°C. Then it maybe no additional thermal shielding would be needed at all as long as wings allow it to reach this low ballistic coefficient.

The ballistic coefficient calculated above is about 60 kg/m2. Then we need 3 times higher cross-sectional area to bring that down to ca. 20 kg/m2, or likely more if we take into account the added mass.

As before with the inflatable conical decelerator we need to know how the ‘parashield’ mass scales with size. This isn’t provided in the research report. It could be by the cube of the diameter or by the square.

I’ll make an estimate based on just the “wings” being a flat sheet of the needed size. The thickness of the Starship walls is about 4mm. But it’s been speculated in a weight optimized design they could be as low as 2mm thick. Then I’ll use stainless steel at 2mm thick.

The hypersonic drag coefficient of a flat sheet is similar to that of a cylinder at ca. 2. Take the added wing cross-section as 36m*50m, added on to the 9*50 = 450 m2 cross-section of the cylindrical Starship. Then with a density of stainless-steel of 7,800 kg/m2, the ballistic coefficient calculates out to be:

(60,000 + .002*36*50*7,800)/2*(450 + 36*50) = 19.6 kg/m2, below the desired 20 kg/m2 point.

According to the assumption the ballistic coefficient is the deciding factor, it could be horizontal wings, delta wing, or the parashields spherical section. Like in the parashield design, additional high-strength spars might need to added to withstand the applied dynamic pressure during the hypersonic/supersonic/subsonic regimes.

But the ‘wing’ is only intended to support the structure on return when the tanks are nearly empty. They might not be able to support it when fully fueled. So the Starship would have to insure to fly a non-lifting trajectory during ascent. It might further be required for the ‘wing’ to be folded away during ascent, only deploying on return.

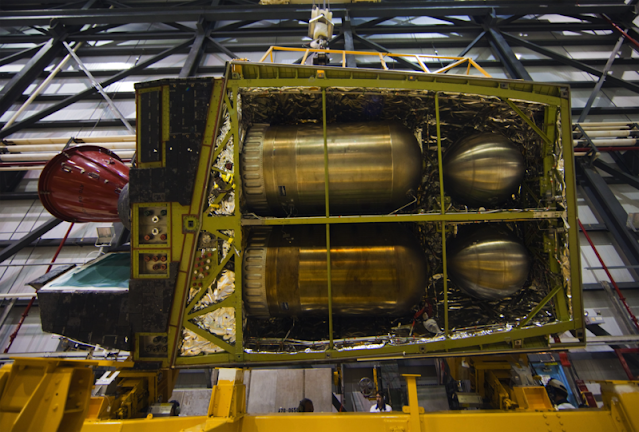

That the wing only supports the nearly empty weight of the structure during return suggests it could be made even thinner. For instance the Centaur V upper stage at a gross weight of ca. 60 tons has stainless-steel tanks walls only 1mm thick:

(60,000 + .001*18*50*7,800)/2*(450 + 18*50) = 24.8 kg/m2.

Given the leeway between the 800°C max temperature at 20 kg/m^2 and the 1,400°C melting point of steel this would likely still be sufficient for the stainless-steel structure not needing further thermal protection.

If the added wing could be made this thin then the added weight would only be .001*18*50*7,800 = 7,020 kg, compared to the 60,000 kg of the Starship dry mass+fairing weight.

The importance of such lightweight orbital decelerators has now increased importance now that the Air Force wants rocket cargo point-to-point delivery:

Air Force picks remote Pacific atoll as site for cargo rocket trials

By SETH ROBSON STARS AND STRIPES • March 4, 2025

https://www.stripes.com/theaters/asia_pacific/2025-03-04/cargo-rocket-pacific-johnston-atoll-air-force-17026030.html

The plan is for fully reusable launchers but note these decelerators could still be used to send the cargo back down to their delivery points even with expendable launchers or partially reusable launchers where the only the first stage is reused and the upper stage is expendable. This means they can be used to delivery cargo now with the Falcon 9, and soon with the Rocket Labs Neutron and Blue Origin’s New Glenn, also planned to be partially reusable.

Sierra Space has also already contracted with the Air Force to deliver supplies that were already preloaded and stored in space to distant locations:

Sierra Space Ghost: Revolutionizing Global Logistics

OCTOBER 3, 2024

https://www.sierraspace.com/press-releases/sierra-space-ghost-revolutionizing-global-logistics/

But the very same method can be used as the orbital decelerator for a rocket cargo point-to-point delivery system. Notably, the Sierra Space method is quite analogous to the Akin’s parashield method.

High Hypersonic Lift/Drag Ratio Used for Return From Orbit.

The above discussed methods are useful for just drag decelerators. But the discussion is incomplete for winged reentry because it does not include the effects of lift. For instance if wings with high lift/drag ratio at hypersonic speeds were used the descent rate would be decreased even further, thus further decreasing the heating rate, and thereby allowing a lighter reentry system. The hypersonic aerodynamics of the Space Shuttle have been described as falling “like a brick” with a quite low hypersonic L/D ratio of about 1, thus necessitating it’s heavy thermal protection. Then wings with high hypersonic L/D ratio could greatly improve on this.

This possibility is discussed here:

Clamshell wings for hypersonic reentry of rocket stages. UPDATED, May 4, 2023.

https://exoscientist.blogspot.com/2023/02/clamshell-wings-for-hypersonic-reentry.html

In this approach there would be no extra added weight for the decelerator at all for a returning rocket stage, just the fairing or propellant tank itself as the wings.

Robert Clark

.png)