Copyright 2023 Robert Clark

In the blog post, "Did SpaceX throttle down the booster engines on the IFT-2 test launch to prevent engine failures?", I suggested that SpaceX was able to get the SuperHeavy booster to complete its portion of the ascent in the last test flight by throttling down the thrust on the Raptor engines to less than 75%, and that the Starship upper stage was not able to because its Raptors were run at ~90%.

Reducing the throttle level reduces the chamber pressure also, from 300 bar to ~225 bar, allowing the Raptor to fire without leaks.

But if SpaceX lowered the thrust level on the booster to prevent engine failures, why did they not also do this on the Starship upper stage? From the propellant level indicators SpaceX provided on the launch video page, we can estimate the remaining propellant on the Starship just prior to FTS as under 100 tons out of a max 1,200 tons.

(

The ship is not visible in this image because of its extreme distance just before it exploded.)

Then we can estimate if the engines were run at less than 75%, the remaining propellant would be in the range of 300 tons. This likely would have been too much SpaceX to reach its goal of getting the Starship to just under orbital velocity:

SpaceX Starship megarocket launches on 2nd-ever test flight, explodes in 'rapid unscheduled disassembly' (video) News.

By Josh Dinner published November 18, 2023

The spacecraft was never expected to reach full orbit around Earth, instead flying on a suborbital trajectory to splash down in the Pacific Ocean off the coast of Hawaii. "We're not targeting orbit today; we're targeting almost orbit," said Siva Bharadvaj, a SpaceX operations engineer, adding that the goal was to "get to a thrust profile similar to what we would need for orbit, but also energy level that the ship would need to dissipate for reentry."

https://www.space.com/spacex-starship-second-test-flight-launch-explodes

So what would be the payload possible if we ran both stages at ~75% thrust? A rough estimate would be at approx. 100 tons as a fully reusable launcher, instead of the 150 tons now. A problem with that is the estimated number of refuelings for the Starship HLS used as an lunar lander was perhaps 16. But if the max payload was only 100 tons, then the number of refuelings would rise to 24.

The idea of using so many refuelings for a lunar landing mission has been controversial. Then we'll look at other approaches. Robert Zubrin has noted it can be done in a single launch by giving the SuperHeavy/Starship a small 3rd stage, a mini Starship.

Elon Musk once suggested an expendable version of the Starship could have a 30 to 1 mass ratio:

__________________________________________________________________

Elon Musk @elonmusk

Mar 29, 2019

Replying to

@Erdayastronaut and @DiscoverMag

Probably no fairing either & just 3 Raptor Vacuum engines. Mass ratio of ~30 (1200 tons full, 40 tons empty) with Isp of 380. Then drop a few dozen modified Starlink satellites from empty engine bays with ~1600 Isp, MR 2. Spread out, see what’s there. Not impossible.

__________________________________________________________________

We'll explore this capability. We'll first look at a case where both the SuperHeavy and Starship are expendable stages. A stage generally gets better mass ratio scaled up, so to begin with we'll start off with an estimated mass ratio for the SuperHeavy as about 30 to 1 with the same propellant load as it is now of 3,400 tons but a dry mass of only 115 tons.

But that 30 to 1 mass ratio of the Starship is with just 3 engines since an upper stage does not need enough thrust to lift off from the ground. The SuperHeavy scaled up then would only have 9 engines, but this would not be enough for liftoff. We'll take the number of engines on this version of the SuperHeavy to be again 33. Then we need an additional 24 engines.

The thrust/weight ratio of the Raptor is about 140 to 1. Assuming we're reducing the operational thrust level of the Raptor to 75%, its thrust would be 0.75*230 tons-force = 172.5 tons-force. At a 140 to 1 T/W ratio its mass would be 1.2 tons. So the additional 24 engines needed would add 24*1.2 = 28.8 tons to the dry mass: 115 + 28.8 = 143.8 tons. Round it up to 150 tons with the additional plumbing and larger thrust structure required.

However, with the lower sea level thrust of our 75%-throttle Raptors, the 2-stage SH/SS would have low T/W ratio. We'll also look at a case of adding small 3rd stage of size ~300 tons. Adding a ~300 ton 3rd stage reduces the T/W to barely above 1. Then it would be advisable to add 2 more Raptors to the booster, bringing it to 35. There should be sufficient room beneath the booster for an additional 2 Raptors.

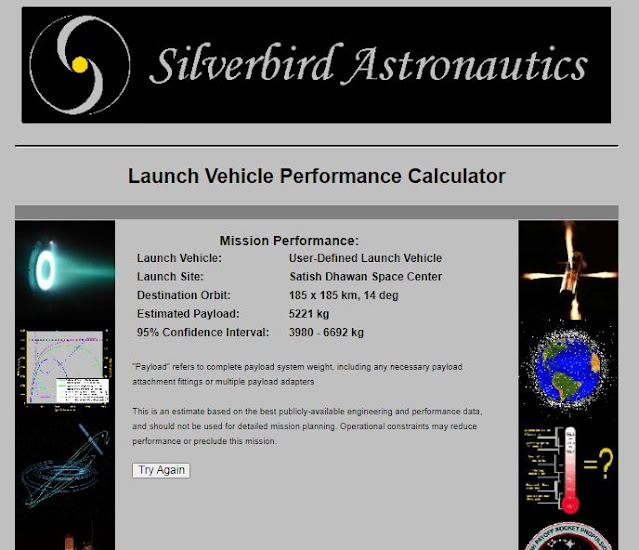

The total thrust of the SuperHeavy at sea level is now 35*172.5 = 5,950 tons-force, 58,400 kiloNewtons(kN). We'll use the SilverbirdAstronautics.com payload estimator. This takes the vacuum Isp and vacuum thrust as inputs even for first stage engines. For the lower chamber pressure, ~ 225 bar corresponding to the reduced thrust, we would also have lower vacuum Isp. Call it about that of the Raptor 1 so ~ 350s. Then the vacuum thrust for this version of the Raptor would be (350/327)*172.5 = 184.6 tons-force. For the 35 SuperHeavy engines that's 35*184.6 = 6,460 tons-force, 63,400 kN vacuum thrust. For the dry mass for the 35 engine stage we'll raise it to 152.4 tons.

For the Starship upper stage, the Raptor Vacuum will still have a vacuum Isp of 380s. However, we are keeping 3 sea level Raptors and 3 vacuum Raptors. Then the average Isp for the upper stage will be 370s. The vacuum thrust calculates out to be 11,500 kN.

With the 3 additional Raptor engines being vacuum engines the added weight will be higher than that of just 3 additional sea level engines. We'll take the dry mass of the new upper stage to be 45,000 kg.

Then the input page to the SilverbirdAstronautics.com page looks like:

And the payload results are:

The expendable payload value of 264 tons is more than the expendable payload of the current SH/SS of 250 tons even-though the new version would be at 75% thrust level. This surprising result must be due the greatly reduced dry mass of both stages.

But even more surprising is the payload possible to translunar injection(TLI). In the SilverbirdAstronautics.com calculator this option is indicated by selecting "Escape Trajectory" for "Destination". In the "Hyperbolic, C3" field enter, -1.0. This number indicates how far beyond escape velocity the flight needs. In this case, it's negative since you don't quite have to get to escape velocity to reach the Moon.

Then the estimated payload is:

The payload would be ~75 tons sent to rendevous with the Moon.This is far beyond what Apollo at ~43 tons or SLS even in its later Block 2 version at ~46 tons to TLI could do as a single launch architecture. This would allow wide latitude in how you would design the in-space stages and lander to reach the surface of the Moon.

A Three-Stage SuperHeavy/Starship/mini-Starship.

A basic principle of spaceflight is high delta-v missions, such as missions to the Moon or Mars, can be done more efficiently with more stages. Robert Zubrin has proposed a "mini-Starship" as a 3rd stage for the SuperHeavy/Starship. He trenchantly observed, "The Starship is a reusable Saturn V. It is not a LEM". Addition of a 3-rd stage would allow even higher payload to the Moon. Say, the mass ratio of ~30 to 1 can be retained for the 3rd stage at ca. 300 propellant load and ca. 10 tons dry mass, using a single Raptor vacuum of 380s Isp and 1,900 kN vacuum thrust. This gives an input page result:

Then the payload to TLI would be ~105 tons:

This is regarding the SH/SS/mini-SS as a launcher analogous to the 3-stage Saturn V for the Apollo missions. This would require additional in-space stage(s) for doing the landing. However, the payload to TLI is so high this mini-Starship could itself serve as the lander for a round-trip mission to the Moon's surface with a capsule or habitat of ~15 tons mass. This is a mass 50% higher than the mass of the Orion capsule that could be carried not just to a lunar orbit planned for Orion, but all the way to the lunar surface and back to Earth again.

Flights to Mars.

Addition of a third stage also allows more efficient flights to Mars in a single launch. This graphic gives the C3 needed for flights to the planets:

For Mars it is about 14 km2

/s2. The TMI payload to Mars is then:

A payload of 86 tons sent towards Mars for trans-Mars injection(TMI) as a single flight architecture.

These are for expendable versions of SuperHeavy/Starship. Elon Musk has estimated the cost of the SH/SS as in the range $100 million to $200 million. Even as expendable this is a greatly reduced cost than the SLS cost of $4 billion per flight.

Estimates of Reusable Payloads.

The reduction of cost of a flight to the Moon and Mars to only a couple of hundred million dollars rather than multi-billions makes the expendable versions worthwhile. But SpaceX is committed to reusability.

Elon has said full reusability would lose 40 to 50% off payload. And even the reusability only for the first stage loses a quite significant 30% from the payload. These are from using powered boost back approach to landing. The propellant that must be kept on reserve, unused during the ascent for the boost back and landing is in the range of 7%. For the 3,400 ton prop load SuperHeavy this ~240 tons. This is doubly disadvantageous for payload in that not only can this prop not be used during flight to orbit but it also acts like additional dead-weight that must be carried in flight.

Elon Musk has said powered, vertical landing is preferred over horizontal, winged landing because it can be used on airless or low atmospheric worlds such as the Moon and Mars. However, SpaceX needs to do a trade study to see which method results in the least payload lost. Wings typically take up about 5 to 10% of the gross weight of an aircraft. For a vertical launch rocket using non-lifting trajectory on ascent to orbit, this 5 to 10% would only have to be of the dry weight of the craft since aerodynamic lift would be used only during return when the stage is nearly empty.

So for the SuperHeavy the added weight of the wings would only have to be 7.5 to 15 tons compared to the 240 tons needed for the vertical landing method. Actually, it likely can be even smaller than the 5%. For one thing rather than using large wings such as used on the Shuttle. It could use short, stubby wings instead. The large wings of the shuttle were due to competing requirements by NASA and the Air Force for where the Shuttle should be able to land.

Examples of how they could look instead might be those of the X-37 and of the Skylon:

For the Skylon by using carbon-fiber the wing weight was only 2% of the landed weight. This is 2% of the full gross weight because it used a horizontal liftoff. But since the Starship will be using a vertical liftoff and non-lifting trajectory, the wings only have to support the weight of the vehicle on return, so that 2% only has to be calculated on just the dry weight. The specialty high strength stainless steel used on the Starship might be preferred for the wings as well since it would have about the same strength but have reduced thermal shielding requirements.

The landing gear weight can be taken as only 3%:

This likely can be reduced by half to ~1.5% by carbon-fiber or the specialty steel used on the Starship.

Finally, the thermal protection such as SpaceX’s PICA-X might only add on additional 8% of the dry weight.

So these extra systems required for reusability will only add a proportionally small amount to the dry mass, and so subtract only a proportionally small amount from the payload.

Bob Clark