Copyright 2023 Robert Clark

(patents pending)

The aerospike is a method of altitude compensation for a rocket nozzle that provides the optimal expansion for the ambient air pressure all the way to orbit. Two ways of doing this is one, to use a toroidal combustion chamber and exhaust the flow down the sides of the spike.

Another way is to use multiple small combustion chambers that each separately exhaust down the sides of the spike.

In both cases the exhaust flow is initiated at only the top of the spike. However, a problem is converting a cylindrical combustion chamber to a toroidal one is an expensive process.

Another problem would be for the case of a Falcon 9 or a SuperHeavy where the entire base area is covered by the multiple engine bells there would be no room to place a spike below it.

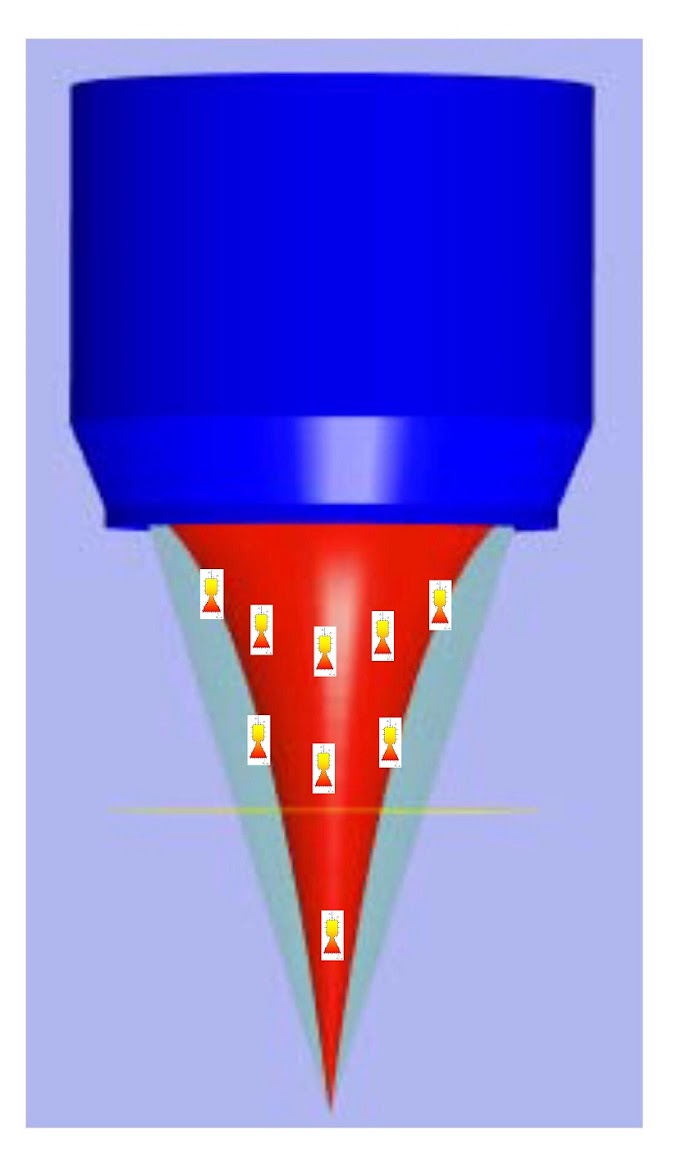

But a way it could be done would be to arrange the various engines in three dimensions down the sides of the spike:

UPDATE, 1/10/2023

The above was for a multi-engine stage. But there is a way to emulate this for a single engine to produce a 3D level exhaust flow as for the multi-engine case.

Imagine concentric rings attached to the bottom of the exhaust nozzle of the single engine

2 comments:

That's a very good explanation of how the aerospike version of the free-expansion nozzle works. However, I would like to point out that the "high-altitude" expansion illustration pertains to altitudes around only 60,000 feet for practical chamber pressures, NOT to the vacuum flow pattern! In vacuum, the edge of the flow pattern is essentially straight out to the side (90 to 94 degrees from the axis, depending upon specific heat ratio). The streamline divergence effect reduces your nozzle kinetic energy efficiency to just about 50% at best, even if there were no other losses. My own recommendation is that these free expansion nozzles are better suited to the first stages in a multi-stage vehicle, but ONLY those with a very low staging altitude. They are just inherently pretty worthless flying out into vacuum, despite the claims otherwise. With a physical bell, divergence angle is limited to the bell lip angle,

with the turn to 90-something degrees happens AFTER the plume has exited at the full area expansion ratio, and so does not affect thrust efficiency. Free expansion designs inherently CANNOT do that, having no physical bell to restrain the divergence anywhere after the throat (or thereabouts). The radical divergence angle that kills efficiency is EXACTLY how area ratio is made "perfect" in a free expansion design. But, expansion ratio AND thrust efficiency TOGETHER create performance! You have to have both! -- GW

High operating pressure in combustion chamber more than compensates for benefits of hypothetical aerospike configuration.

Post a Comment