Copyright 2022 Robert Clark

SpaceX has decided that the Raptors will first be used on the Superheavy/Starship, and perhaps even to only to be used on these vehicles. That SpaceX wants to put the Raptors on SH/SS is understandable since they want a super heavy lift rocket for Mars flights. However, Elon Musk has also spoken about opening up the space frontier. Then using the Raptors only on the largest space vehicles is the opposite of what they should be doing.

SpaceX shows great insight in wanting to produce fully reusable space vehicles since throughout history reusable transport vehicles have always been used. But in their approach to the SH/SS they are missing an extremely important fact. By insisting the SH/SS must be the be-all-end-all for ALL spaceflight they are ignoring the fact transport vehicles going back even to the horse-drawn era have always come in different sizes.

SpaceX seems to be operating under the assumption making only this largest transport vehicle will be a competitive advantage in regards to size of the cargo that can be carried, therefore lowering the cost per kilo to orbit. But actually this is fallacious. It would be like trying to argue it would be optimal to only allow Greyhound buses and tractor trailers on the roads with no smaller vehicles allowed. In actuality, the number of transport vehicles on the road of various sizes from small to large is why the amount of transport, both cargo and human is so large.

One might attempt to argue perhaps air transport would be more relevant to the question of only allowing the largest of transport vehicles to fly to space. But even here the argument is just as fallacious: the amount of transport by the wide-body aircraft is a tiny proportion of the amount of air transport occurring:

Instead of their current approach, the SpaceX plan should be to allow other companies to use the Raptor in their own space vehicles. It is a fact that the engine is the most expensive development of a space vehicle. SpaceX is intending to produce the Raptor in high volume to reduce their cost.

The cost of the Raptor is trending down to only $1 million per engine. By allowing space companies to purchase the Raptor would greatly reduce their development cost for their own rockets.

Calculations for Smaller Launchers.

It's puzzling why for so many years it was said SSTO's were not feasible or not with significant payload with current technology. Actually, high payload SSTO's are well within current tech and have been since the 70's with the advent of the staged-combustion, high-performance SSME hydrogen-fueled engines in the U.S. and the kerosene-fueled RD-180 and RD-170 engines in Russia.

We now have the advent of the Raptor staged-combustion, high performance methane-fueled engine. This also makes possible SSTO with high payload: any of the current or past kerosene-fueled engines could become SSTO's when switched out to methane-fueled using the Raptor engine. The advantage is the Raptor engine in high volume production would be low cost.

The Atlas I.

This was the original rocket from the 60's that first sent John Glenn to orbit. At the time the engines were not advanced enough for SSTO. Because of the limited engines, extraordinary lengths were endeavored to reduced weight, including what were called "balloon tanks". These were tanks that maintained their structural integrity in simply being pressurized, to the extent they could not support their own weight if left unfueled or unpressurized. From the Astronautix web page:

SLV-3 Atlas / Agena B.

Family: Atlas. Country: USA. Status: Hardware. Department of

Defence Designation: SLV-3.

Standardized Atlas booster with Agena B upper stage.

Specifications

Payload: 600 kg. to a: 19,500 x 103,000 km orbit at 77.5 deg

inclination trajectory.

Stage Number: 0. 1 x Atlas MA-3 Gross Mass: 3,174 kg. Empty Mass:

3,174 kg. Thrust (vac): 167,740 kgf. Isp: 290 sec. Burn time: 120 sec.

Isp(sl): 256 sec. Diameter: 4.9 m. Span: 4.9 m. Length: 0.0 m.

Propellants: Lox/Kerosene No Engines: 2. LR-89-5

Stage Number: 1. 1 x Atlas Agena SLV-3 Gross Mass: 117,026 kg.

Empty Mass: 2,326 kg. Thrust (vac): 39,400 kgf. Isp: 316 sec. Burn

time: 265 sec. Isp(sl): 220 sec. Diameter: 3.1 m. Span: 4.9 m. Length:

20.7 m. Propellants: Lox/Kerosene No Engines: 1. LR-105-5

Stage Number: 2. 1 x Agena B Gross Mass: 7,167 kg. Empty Mass: 867

kg. Thrust (vac): 7,257 kgf. Isp: 285 sec. Burn time: 240 sec. Isp(sl): 0

sec. Diameter: 1.5 m. Span: 1.5 m. Length: 7.1 m. Propellants: Nitric

acid/UDMH No Engines: 1. Bell 8081http://www.astronautix.com/a/atlasslv-3agenab.html

You see the Stage 1 had a surprisingly high mass ratio of 50 to 1(!). However, the Atlas I was unusual in that it had a drop engine, listed here as Stage Number 0, that provided most of the lift-off thrust. The Stage Number 1 listed here had what was called a sustainer engine that flew the rest of the flight but did not have enough thrust for lift-off. So we'll remove that and replace it with the Raptor 2 sea level engine. This upgraded Raptor has an increased sea level thrust of 230-tons, with only slightly reduced vacuum Isp of ~ 350s. The Raptor 2 at 1,500 kg mass weighs about 1,000 kg more than the engine original used on the Atlas I Stage Number 1, so call the stage dry mass as 3,326 kg.

Normally methane-LOX propellant has a density of 800 kg/m^3 compared to 1,000 kg/m^3 for kerosene-LOX. But with supercooling the density of methane-LOX is about that of kerosene-LOX so we'll leave the propellant mass amounts the same in the calculations below.

Then using a delta-v to orbit of ~9,150 m/s we can get ~5 tons to orbit for this Raptor powered Atlas I:

350*9.81Ln(1 + 114.7/(3.3 + 5)) = 9,250 m/s.

The Falcon 9 1st and 2nd stage.

For the Falcon 9 1st stage:

| Type | Falcon 9 FT Stage 1 |

| Length | 42.6 m (47m w/ Interstage) |

| Diameter | 3.66 m |

| Inert Mass | ~22,200 kg (est.) |

| Propellant Mass | 411,000 kg (According to FAA) |

| Fuel | Rocket Propellant 1 |

| Oxidizer | Liquid Oxygen |

| LOX Mass | 287,430 kg |

| RP-1 Mass | 123,570 kg |

| LOX Volume | 234,700 l |

| RP-1 Volume | 143,900 l |

| LOX Tank | Monocoque |

| RP-1 Tank | Stringer & Ring Frame |

| Material | Aluminum-Lithium |

| Interstage Length | 4.5 m (est.) |

| Guidance | From 2nd Stage |

| Tank Pressurization | Heated Helium |

| Propulsion | 9 x Merlin 1D |

| Engine Arrangement | Octaweb |

The 9 Merlin engines had a total sea level thrust of 775 tons-force. We'll replace them with three Raptor 2 sea level engines of total 690 tons-force sea level thrust. It will be about 300 kilos increased weight for the engines so we'll use a dry weight of 22.5 tons. Then using the 350s Isp we get a ~8 ton payload:

350*9.81Ln(1 + 411/(22.5 + 8)) = 9,175 m/s. sufficient for LEO.

For the Falcon 9 2nd stage:

| Type | Falcon 9 FT Stage 2 |

| Length | 12.6m (Separated Length) |

| Diameter | 3.66 m |

| Inert Mass | 4,000 kg (est.) |

| Propellant Mass | 107,500 kg (est.) |

| Fuel | Rocket Propellant 1 |

| Oxidizer | Liquid Oxygen |

| LOX Mass | 75,200 kg (est.) |

| RP-1 Mass | 32,300 kg (est.) |

| LOX Tank | Monocoque |

| RP-1 Tank | Monocoque |

| Material | Aluminum-Lithium |

| Guidance | Inertial |

| Tank Pressurization | Heated Helium |

| Propulsion | 1 x Merlin 1D Vac |

| Engine Type | Gas Generator |

| Propellant Feed | Turbopump |

| Thrust | 934kN |

| Engine Dry Weight | ~490kg |

| Burn Time | 397 s |

| Specific Impulse | 348s |

| Chamber Pressure | >9.7MPa (M1D Standard) |

| Expansion Ratio | 165 |

We'll only need a single Raptor 2 here to swap out the Merlin Vacuum engine. The Raptor weighs about 1,000 kilos more, so call the new dry mass 5,000 kg. Then this could get 3,000 kg to LEO:

350*9.81Ln(1 + 107.5/(5 + 3)) = 9,160 m/s.

Note for both these cases the payload fraction will be 2% - 3%, which is in the range common for expendable rockets, countering the myth SSTO's can't carry significant payload. Actually, for both these cases the payload would be somewhat more because the simple rocket equation estimate doesn't take into account take-off thrust/weight ratio which is high in these two cases, which will increase the actual payload.

The capability of an SSTO to carry significant payload is still controversial, however. So we'll look at a two-stage-to-orbit version of a Raptor powered version of the F9. Note here the upper stage only fires at high altitude so we can use the vacuum version of the Raptor with a ~380s vacuum Isp. Then we can get ~34 tons to LEO:

350*9.81Ln(1 + 411/(22.5 + 112.5 + 34)) + 380*9.81Ln(1 +107.5/(5 + 34)) = 9,160 m/s, sufficient for orbit with a 34 ton payload. This is a 50% improvement over the current F9 expendable payload of 22 tons.

For a ~200-ton gross mass vehicle.

We will be basing cost estimates on the first version of the Falcon 9, now called v1.0, a ~300 ton gross mass vehicle. However, for cost reasons we're considering launchers as single stage launchable by a single Raptor, so we'll take our stage as approx. 200-tons gross mass. Take the propellant load of the stage as ~200 tons. For both the 1st and 2nd stages of the current Falcon 9 with the Merlins swapped out to use Raptors, we saw above both stages had mass ratios of about 20 to 1. So assume the mass ratio as about 20 to 1 with this new launcher, with an ~10 ton dry mass. Then the rocket equation gives:

350*9.81Ln(1 + 200/(10 + 5)) = 9,140 m/s, sufficient for a payload of 5 tons to LEO.

Cost Estimates.

SpaceX shocked the space industry by developing the original version of the Falcon 9, now called Falcon 9 v1.0, at only a $300 million development cost:

Falcon 9.

In 2011, SpaceX estimated that Falcon 9 v1.0 development costs were on the order of US$300 million.[39] NASA estimated development costs of US$3.6 billion had a traditional cost-plus contract approach been used.[40] A 2011 NASA report "estimated that it would have cost the agency about US$4 billion to develop a rocket like the Falcon 9 booster based upon NASA's traditional contracting processes" while "a more commercial development" approach might have allowed the agency to pay only US$1.7 billion".[41]

This was only a tenth of the development cost of a usual government-financed launcher of this size, approx. 300 tons gross mass. Note too developing a new engine makes up the lion-share of the development of a new rocket. Look for example at this breakdown of of the development costs of the Ariane 5 rocket:

Development budget

Again, Ariane 5, from 'Europäische Tragerraketen, band 2', Bernd Leitenberger:

Studies and tests 125

solid boosters 355

H120 first stage 270

HM60 (Vulcain) engine and test stands 738

other elements of the first stage and boosters 95

upper stage and VEB 200

ground support in Europe 80

Buildings and other structures in Kourou (launch pad) 450

Test flights 185

Total 2498

ESA and CNES management 102

https://space.stackexchange.com/questions/17777/what-is-the-rough-breakdown-of-rocket-costs

For our scenario we would not be using solid rockets, nor using an upper stage. For the Ariane 5, the ESA also built entire new launch facilities in Kourou, Guyana in equatorial Africa, while we'll assume using existing NASA facilities for our launch. Of the remaining costs, you see the Vulcain engine development cost was more than half the remaining costs, and far more than the Ariane 5 core stage itself.

So without new engine development, the development of a new 300 ton gross mass rocket might be less than a $150 million cost. So for our ~200-ton gross mass vehicle, estimate it as 2/3rds of that, so ~$100 million development cost. And for a 100-ton gross mass rocket perhaps 1/3rd of that so only $50 million. Note, we'll be following the SpaceX low cost commercial-space approach to rocket development, to be sure.

As an example of a smaller launch vehicle commercial-space development cost,

the SpaceX Falcon 1 cost about $90 million, but this was with the Merlin engine development cost. Without that, the development might have been less than half of that, or less than $45 million. Note too, the Falcon 1 development cost included the development of the upper stage and its separate engine. Then following the Ariane 5 costing model, we might estimate the development cost of the first stage only without engine development cost, as a only a quarter of the total development cost, so only ~$25 million.

As another example of development cost of a smaller rocket, consider the DC-X suborbital demonstrator rocket.

This had a development cost of $60 million. It used off-the-shelf hydrogen-fueled RL-10A engines, saving on engine development costs. The DC-X was at about 9,000 kilo hydrogen-oxygen propellant load. Since kerosene-LOX or supercooled methane-LOX as propellant is three times as dense this would correspond to a vehicle of similar dimensions but of 3 times larger propellant load so ca. 27,000 kilos, about the size of the Falcon 1.

What about the cost of a launch to the customer? Note that when a launch company prices its launches it includes in that an amount to cover its development cost after some number of launches. The actual production cost of a launcher will be several times less than the cost charged to the customer for a launch.

So for the approx. 200-ton gross mass vehicle the price for the stage without the engine cost might be 1/10th of $100 million, or $10 million. And the cost with the Raptor engine added on?

Customer Pricing for the Raptor Engine.

The $1 million estimated cost of the Raptor when produced in volume will actually be the production cost to SpaceX. Remember the price for the engine SpaceX will charge the customer will include some amount to cover development cost. We don't know that development cost for the Raptor so we cant use the 1/10th estimate. Plus, this will be when SpaceX is producing the engine in high volume where that initial pricing estimate will likely not be valid.

For lack of a better estimate we'll compare the customer pricing for the current version of the Falcon 9 to SpaceX's production costs of a single rocket:

INNOVATION

SPACEX: ELON MUSK BREAKS DOWN THE COST OF REUSABLE ROCKETS

SpaceX CEO Elon Musk has lifted the lid on why reusing Falcon 9 boosters makes long-term economic sense.

...

In terms of the marginal costs, the costs associated with producing just one extra rocket, Musk also recently shed some further light on the figures. In an interview with Aviation Week in May, Musk listed the marginal cost of a Falcon 9 at $15 million in the best case. He also listed the cost of refurbishing a booster at $1 million. This would fit with Musk's most recent claim that the costs of refurbishment make up less than 10 percent of the booster costs.

So the price of the Falcon 9 of $60 million is about 4 times that of the production cost. Then based on that we might expect the price to the customer of $4 million, bringing the price of 200-ton gross mass 5-ton payload mass single stage to $14 million.

Reusable Launcher.

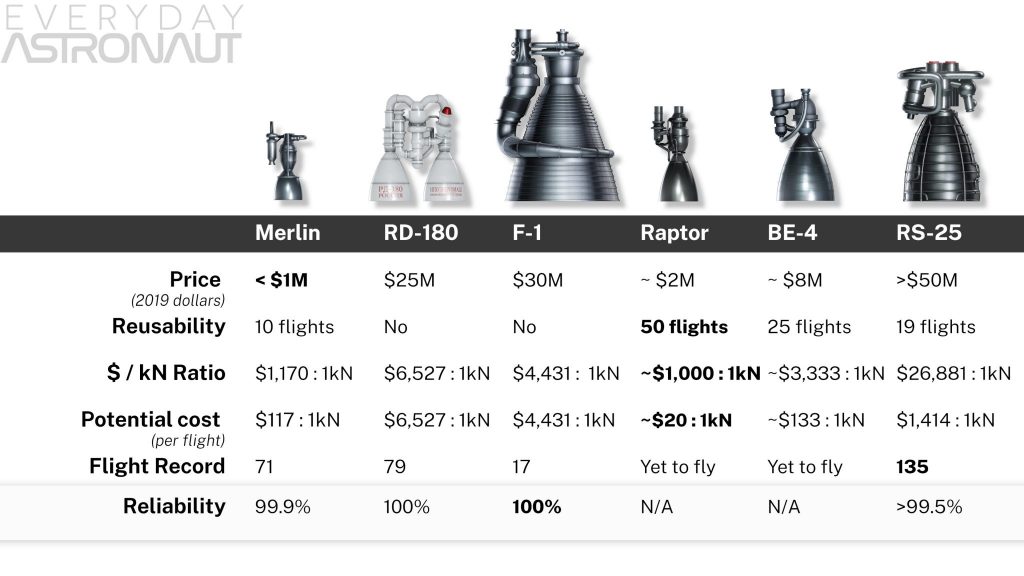

These though would be the expendable prices. According to Tim Dodd, the "Everyday Astronaut", the Raptor engine is expected to be reusable 50 times:

Then if the maintenance cost is small compared to the launch cost, at the $11 million price point, that would be approx. $220,000 per launch.

And the price per kilo for a reusable version? That would be dependent on the how much the extra mass for reusability systems subtract from the payload.

Heat Shield and Landing Legs.

We'll envision this as a VTVL (vertical take-off vertical landing) SSTO. Then we need to add heat shield, and landing legs. For weight of the heat shield, from the Apollo era it was about 15% of the weight of the reentry vehicle. However, SpaceX's PICA-X is about half the weight so about 7.5% of the landed weight, approx. the dry weight.

Besides that, non-ablative thermal protection is now available at similar light-weight to PICA-X:

TPS Materials and Costs for Future Reusable Launch Vehicles.

For the landing legs, that is commonly estimated as 3% of the landed weight:

However, with modern composite materials we can probably get it to be half that. So call it 1.5% of the landed weight, which is approx. the stage dry weight.

Propellant for landing.

I remember thinking when reading of the debate about reusable vehicles between proponents of horizontal winged and vertical propulsive landing that all this debate was about a measly 100 m/s delta-v. as for example discussed here:

The reason is whether you use wings or not almost all the speed of orbital velocity is going to be killed off aerodynamically on return. For even for vertical landing, the stage entering broadside will be slowed to terminal velocity, approx. 100 m/s. This is only about 1.3% that of orbital velocity of 7,800 m/s.

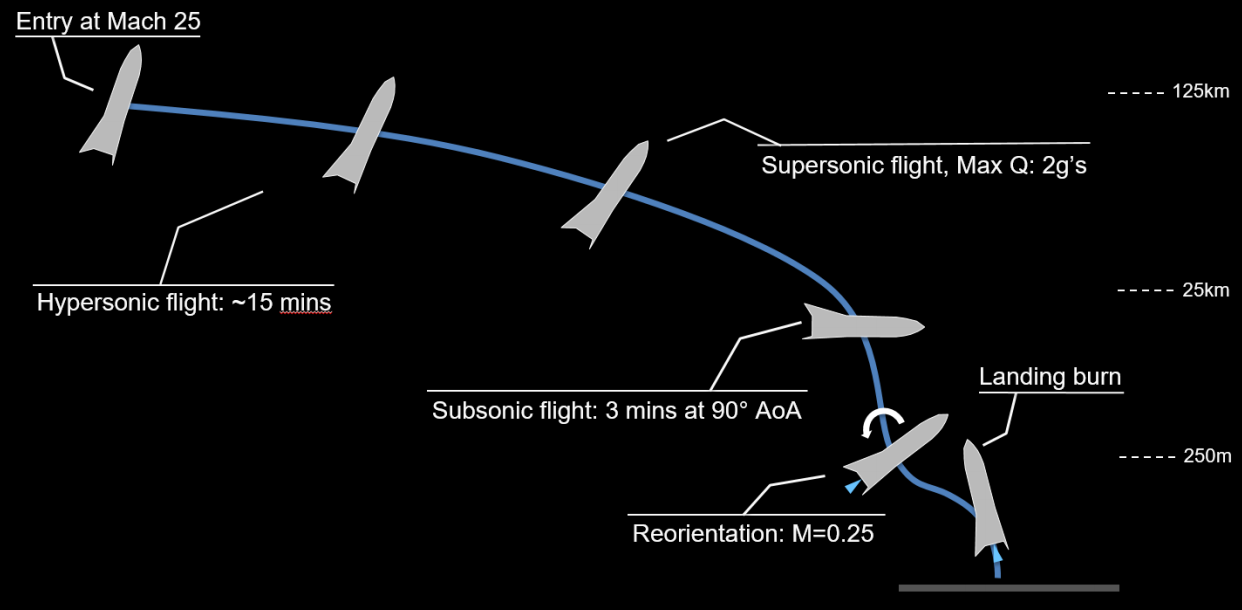

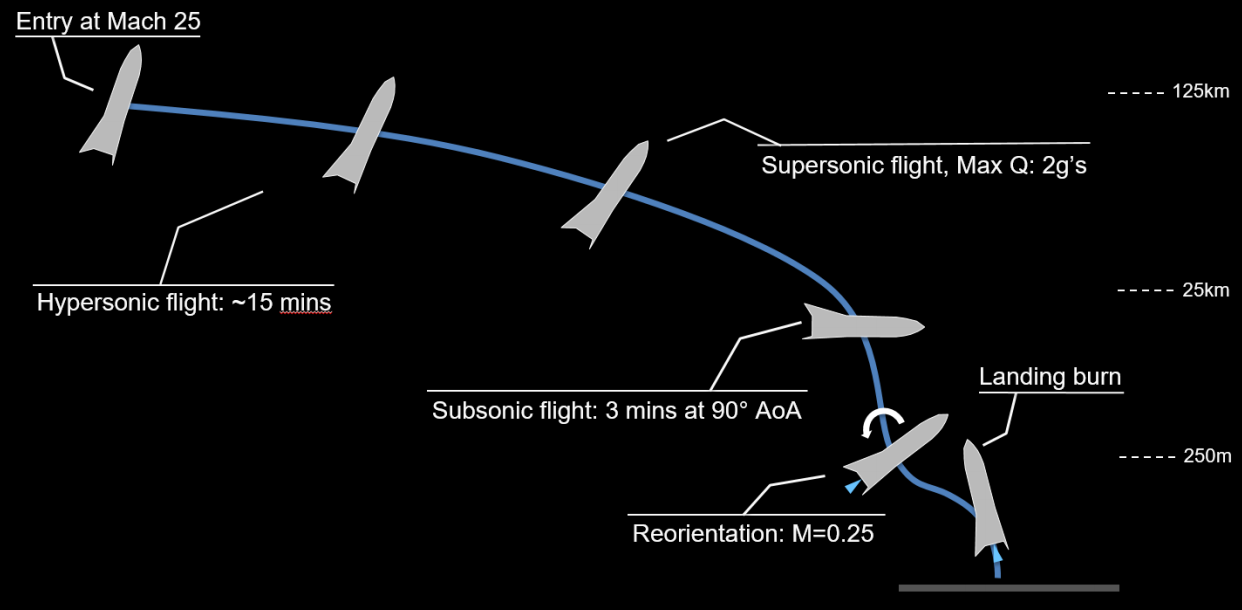

This was confirmed by a graphic just released by SpaceX about the BFR’s Starship upper stage reentry:

This shows for the a vertically landed stage, it only has to fire the engines at about Mach 0.25, 80 m/s. So it only has to kill off 80 m/s propulsively. But with the stage just needing to kill off a 80 m/s velocity with a 3,300 m/s Raptor sea level exhaust velocity, about 330s Isp, by the rocket equation the mass ratio to do this is e[80/3300] = 1.025. Subtracting 1 from this is the ratio of the propellant required to the dry mass, about 2.5%. All together that's 11.5% of the dry mass, or only about 1 ton lost due to reusability.

Then at that $220,000 cost per flight for a 50 use reusable launcher, at a 4,000 kilo payload as reusable, the per kilo cost would be $220,000/4,000kg = $55/kilo.

Robert Clark

Adjunct Professor

Dept. of Mathematics

Widener University

Chester, PA USA

.JPG)

.JPG)