Copyright 2019 Robert Clark

Rocket equation calculation of payload with altitude compensation.

In the blog post "SpaceX BFR tanker as an SSTO", I discussed that the tanker version of the BFR upper stage can be SSTO. This is the version of the upper stage without the crew quarters for up to 100 colonists headed for a months long trip to Mars, therefore has a much lighter structural mass.

However, for the version of the upper stage carrying crew quarters which Elon has called the BFS, for "Starship", Elon has said via twitter it couldn't carry payload as an SSTO:

Verified account

@elonmusk

Replying to @ludan27 @Erdayastronaut and 3 others

Yes, but single stage to orbit with no payload is pointless. Add Super Heavy rocket booster & orbital payload is gigantic. Only need booster on Earth, due to deep gravity well & thick atmosphere. Starship alone on moons & Mars.

6:00 PM - 22 Dec 2018

https://twitter.com/elonmusk/status/1076613555091234816

The SpaceX Raptor engine is expected to have quite high chamber pressure, ca. 200 to 300 bar. So the sea level version gets quite good sea level Isp, 330s, and vacuum ISP, 356s. Still the vacuum Raptor gets 382s Isp in vacuum. So I used the rocket equation to estimate the payload under these two vacuum Isp values.

LEO delta-v is 30,000 ft./sec, 9,150 m/s:

From Modern Engineering for Design of Liquid-Propellant Rocket Engines, p. 12.

https://books.google.com/books?id=TKdIbLX51NQC&pg=PA12&source=gbs_toc_r&cad=4#v=onepage&q&f=false

The BFR upper stage has 85 ton dry mass, 1,100 propellant mass. Then the sea level Raptor gets barely more than 1 ton to orbit in payload:

356*9.81Ln(1 + 1,100/(85 + 1.3)) = 9,152.6 m/s.

But the vacuum Raptor with 382s vacuum Isp gets nearly 20(!) tons:

382*9.81Ln(1 + 1,100/(85 + 19.8)) = 9,151.2 m/s

So using alt.comp. on the sea level Raptors so they can launch from ground yet still get the full 382 Isp of the vacuum Raptors would have major advantages as an SSTO. Note that 20 tons payload would be enough for both 100 passengers and their cargo.

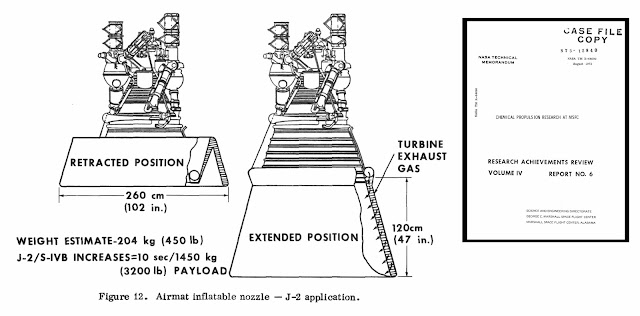

The key holdup is that retrofitting usual cylindrical combustion chamber engines to use annular combustion chambers for aerospike nozzles is expensive and time-consuming. Cheaper, faster, and just as effective is to use nozzle extensions. See the J-2X discussion here:

https://web.archive.org/web/20190327061119/http://www.alternatewars.com/BBOW/Space_Engines/J-2X_Airmat_DWG.png

Remarkable that such a relatively small increase in Isp, results in such a DRASTIC increase in payload, from 1 ton to 20 tons(!) Or said another way, a 7% increase in Isp results in a 1,900% increase in payload! Of course it stems from the exponential nature of the rocket equation.

I admit I was surprised myself when I did the calculation. We’re familiar with the “tyranny of the rocket equation” for making spaceflight hard. But we forget how beneficial it can be when small, and achievable, increases in Isp result in radical increases in payload. I like to call it the beneficence of the rocket equation.

The Aerospike.

Figure 1: Left: an annularly configured aerospike nozzle. Right: a linear aerospike nozzle. Images courtesy Garvey Spacecraft Corp. & Lockheed Martin Corp.

SIMULATION OF AN OXIDIZER-COOLED HYBRID ROCKET THROAT: METHODOLOGY VALIDATION FOR DESIGN OF A COOLED AEROSPIKE NOZZLE

I considered the nozzle extension approach to altitude compensation rather than an aerospike since retrofitting an annular combustion chamber for the aerospike to a usual cylindrical combustion chamber engine would be expensive and time consuming.

However, another approach to an aerospike is to use multiple small engines arrayed around a central spike. This is the approach taken by engineer Philip Bono in his SSTO designs such as the Pegasus and Ithacus in the 60's.

This was also the approach of the 90's proposed SSTO, the X-33/VentureStar.

And the approach by the new space start-up Vector Space.

However, the objection could be made that the large engine bells of the Raptors would not allow enough space for a central spike underneath the stage.

But for this approach you would cut down the size of the nozzles since some of the expansion would be done by the aerospike. We can estimate the size of the new nozzles.

The NASA page on "Isentropic Flow" has a calculator for calculating the pressure ratio of a rocket, based on the specifications of the engine such as specific heat ratio and area expansion ratio:

Gamma is specific heat ratio, about 1.2 for LOX/methane. The pressure ratio is the pressure at the nozzle exit to the combustion chamber pressure. Here it's 0.0021, about 1 to 500. Assuming the combustion chamber pressure for the Raptor is 250 bar, this means the nozzle exit pressure is 1/2 bar.

We'll cut down the nozzle size, so also the area expansion ratio, so that the exit pressure is actually that of sea level. For the NASA calculator, we'll choose the pressure ratio as one of the inputs, set at 1/250 = 0.004. Then the nozzle area ratio is given as 24 to 1:

This means the diameter of the shortened nozzle would be smaller by a factor of sqrt(40/24) = 1.29. Since the diameter of the sea level Raptor is 1.3 m, the shortened nozzle would have a diameter of about 1 m. Then the seven sea level Raptors now with 1 m diameter nozzles arranged around the outer portion of the 9 m wide stage base would leave room for a 7 meter wide central aerospike.

The engines would have their nozzles shortened so that the exit pressure is that of sea level. Commonly with sea level engines, the nozzles are overexpanded so that the exit pressure is actually below sea level. The reason is that sea level engines also have to operate at near vacuum so some intermediate level of expansion is used.

It might even be better than this. The seven Raptors would have alot of empty space around the aerospike. This likely result in a loss of efficiency. We might want instead to use flattened nozzles so that all together they cover the perimeter of the aerospike, as for instance in the image of the Vector Space aerospike nozzle above.

This approach may even work for the 31 Raptors under the first stage booster to allow a central aerospike in that case as well.

Aerospike attachment to a standard bell nozzle.

It might also be possible to give the individual Raptors an aerospike nozzle. One possible way would be by the "double-aerospike"(patent pending):

This avoids the complexity and expense of converting a cylindrical combustion chamber engine to a toroidal one by attaching this "double-aerospike" to the bottom of the bell nozzle. Since sea level engines are already set up as overexpanded, the internal spike would cut down the exit area so the area expansion ratio would be set to make the nozzle exit pressure be equal to sea level. Then the outer aerospike would perform the usual role of altitude compensation.

A problem would be heating at the point of the spike, as it is at the point for the usual outward aerospike, but especially so for the inner spike since it will be closer to the combustion chamber temperatures.

A possible solution would be the ultra high temperature ceramics coming into use in aerospace:

Ceramic matrix composites make inroads in aerospace.

Published on May 14th, 2013 | Edited by: Jim Destefani

It is notable that this jet engine uses an aerospike, or more commonly called plug nozzle for aircraft engines. In fact plug nozzles have been used for decades for jet engines to improve efficiency at high altitude.

It is therefore puzzling why they have not been adopted for rocket engines. For jet aircraft the cruising altitude night be in the range of 30,000 ft, where the air density would be about 1/3rd that of sea level. Using plug nozzles on aircraft improves payload capacity a few percent. However, for rocket engines on a first stage, they have to operate from sea level to near vacuum. For use as an SSTO, with altitude compensation, the payload can then be improved multiple times.

Some ultra high temperature ceramics have melting points above 3,900° C. These high temperature materials can also be used in concert with circulating coolant such as with regenerative cooling of rocket engines, as described here:

Ceramic Materials for Reusable Liquid Fueled Rocket Engine Combustion Devices.

Captain Steven Steel

Materials And Manufacturing Directorate

Air Force Research Laboratory

Wright-Patterson AFB, OH

http://rocket-propulsion.info/resources/articles/Ceramic_Materials_For_LPRE.pdf

Moreover, these ceramic nozzles and engine components can greatly reduce the engine weight:

Sustainable Energy

A More Efficient Jet Engine Is Made from Lighter Parts, Some 3-D Printed.

Composite and 3-D-printed components will mean jet engines that use 15 percent less fuel.

by Kevin Bullis May 14, 2013

Improvement in lift-off thrust using altitude compensation.

Altitude compensation is most known for its ability to allow sea level engines to have higher Isp and thrust under vacuum and near vacuum conditions. However, it is notable it can also allow improved Isp and thrust at sea level.

The reason is, as mentioned before, sea level engines are commonly overexpanded to improve their performance in vacuum. This however reduces their performance at sea level. This reduction is quantified by the formula:

F = q × Ve + (Pe - Pa) × Ae

where F = Thrust

q = Propellant mass flow rate

Ve = Velocity of exhaust gases

Pe = Pressure at nozzle exit

Pa = Ambient pressure

Ae = Area of nozzle exit

http://www.braeunig.us/space/sup1.htm

We estimated above using the NASA online calculator the exit pressure of the usual sea level Raptor as 1/2 bar, 50,000 Pascals(Pa). The diameter is 1.3 m for the sea level Raptor. Then the thrust loss at sea level is (50,000-100,000) × π × (1.3/2)2 = 66,400 N, 6,760 kilogram-force, about 4% of the sea level thrust of 1,700 kN.

Or said another way, using an altitude compensating nozzle can increase the sea level thrust 4%. As the altitude increases, the difference will reduce until the rocket reaches the current nozzles designed set altitude. However, thereafter the improvement in thrust and ISP will again increase until it reaches the max 7% vacuum improvement.

Bob Clark

https://books.google.com/books?id=TKdIbLX51NQC&pg=PA12&source=gbs_toc_r&cad=4#v=onepage&q&f=false

The BFR upper stage has 85 ton dry mass, 1,100 propellant mass. Then the sea level Raptor gets barely more than 1 ton to orbit in payload:

356*9.81Ln(1 + 1,100/(85 + 1.3)) = 9,152.6 m/s.

But the vacuum Raptor with 382s vacuum Isp gets nearly 20(!) tons:

382*9.81Ln(1 + 1,100/(85 + 19.8)) = 9,151.2 m/s

So using alt.comp. on the sea level Raptors so they can launch from ground yet still get the full 382 Isp of the vacuum Raptors would have major advantages as an SSTO. Note that 20 tons payload would be enough for both 100 passengers and their cargo.

The key holdup is that retrofitting usual cylindrical combustion chamber engines to use annular combustion chambers for aerospike nozzles is expensive and time-consuming. Cheaper, faster, and just as effective is to use nozzle extensions. See the J-2X discussion here:

https://web.archive.org/web/20190327061119/http://www.alternatewars.com/BBOW/Space_Engines/J-2X_Airmat_DWG.png

I admit I was surprised myself when I did the calculation. We’re familiar with the “tyranny of the rocket equation” for making spaceflight hard. But we forget how beneficial it can be when small, and achievable, increases in Isp result in radical increases in payload. I like to call it the beneficence of the rocket equation.

The Aerospike.

Figure 1: Left: an annularly configured aerospike nozzle. Right: a linear aerospike nozzle. Images courtesy Garvey Spacecraft Corp. & Lockheed Martin Corp.

SIMULATION OF AN OXIDIZER-COOLED HYBRID ROCKET THROAT: METHODOLOGY VALIDATION FOR DESIGN OF A COOLED AEROSPIKE NOZZLE

I considered the nozzle extension approach to altitude compensation rather than an aerospike since retrofitting an annular combustion chamber for the aerospike to a usual cylindrical combustion chamber engine would be expensive and time consuming.

However, another approach to an aerospike is to use multiple small engines arrayed around a central spike. This is the approach taken by engineer Philip Bono in his SSTO designs such as the Pegasus and Ithacus in the 60's.

Philip Bono with a model of the Pegasus vehicle [IMG: Douglas Aircraft]

Straight back down to Earth: A history of the Vertical Takeoff/Vertical Landing Rocket – Part 1.This was also the approach of the 90's proposed SSTO, the X-33/VentureStar.

And the approach by the new space start-up Vector Space.

But for this approach you would cut down the size of the nozzles since some of the expansion would be done by the aerospike. We can estimate the size of the new nozzles.

The NASA page on "Isentropic Flow" has a calculator for calculating the pressure ratio of a rocket, based on the specifications of the engine such as specific heat ratio and area expansion ratio:

Gamma is specific heat ratio, about 1.2 for LOX/methane. The pressure ratio is the pressure at the nozzle exit to the combustion chamber pressure. Here it's 0.0021, about 1 to 500. Assuming the combustion chamber pressure for the Raptor is 250 bar, this means the nozzle exit pressure is 1/2 bar.

We'll cut down the nozzle size, so also the area expansion ratio, so that the exit pressure is actually that of sea level. For the NASA calculator, we'll choose the pressure ratio as one of the inputs, set at 1/250 = 0.004. Then the nozzle area ratio is given as 24 to 1:

This means the diameter of the shortened nozzle would be smaller by a factor of sqrt(40/24) = 1.29. Since the diameter of the sea level Raptor is 1.3 m, the shortened nozzle would have a diameter of about 1 m. Then the seven sea level Raptors now with 1 m diameter nozzles arranged around the outer portion of the 9 m wide stage base would leave room for a 7 meter wide central aerospike.

The engines would have their nozzles shortened so that the exit pressure is that of sea level. Commonly with sea level engines, the nozzles are overexpanded so that the exit pressure is actually below sea level. The reason is that sea level engines also have to operate at near vacuum so some intermediate level of expansion is used.

It might even be better than this. The seven Raptors would have alot of empty space around the aerospike. This likely result in a loss of efficiency. We might want instead to use flattened nozzles so that all together they cover the perimeter of the aerospike, as for instance in the image of the Vector Space aerospike nozzle above.

This approach may even work for the 31 Raptors under the first stage booster to allow a central aerospike in that case as well.

Aerospike attachment to a standard bell nozzle.

It might also be possible to give the individual Raptors an aerospike nozzle. One possible way would be by the "double-aerospike"(patent pending):

This avoids the complexity and expense of converting a cylindrical combustion chamber engine to a toroidal one by attaching this "double-aerospike" to the bottom of the bell nozzle. Since sea level engines are already set up as overexpanded, the internal spike would cut down the exit area so the area expansion ratio would be set to make the nozzle exit pressure be equal to sea level. Then the outer aerospike would perform the usual role of altitude compensation.

A problem would be heating at the point of the spike, as it is at the point for the usual outward aerospike, but especially so for the inner spike since it will be closer to the combustion chamber temperatures.

A possible solution would be the ultra high temperature ceramics coming into use in aerospace:

Ceramic matrix composites make inroads in aerospace.

Published on May 14th, 2013 | Edited by: Jim Destefani

Oxide CMC exhaust ground test demonstrator consists of a 1.60-m diameter nozzle and 1.14-m diameter × 2.34-m conical centerbody with titanium end cap inspection portal. Credit: Steyer; IJACT.

https://ceramics.org/ceramic-tech-today/ceramic-matrix-composites-make-inroads-in-aerospaceIt is notable that this jet engine uses an aerospike, or more commonly called plug nozzle for aircraft engines. In fact plug nozzles have been used for decades for jet engines to improve efficiency at high altitude.

It is therefore puzzling why they have not been adopted for rocket engines. For jet aircraft the cruising altitude night be in the range of 30,000 ft, where the air density would be about 1/3rd that of sea level. Using plug nozzles on aircraft improves payload capacity a few percent. However, for rocket engines on a first stage, they have to operate from sea level to near vacuum. For use as an SSTO, with altitude compensation, the payload can then be improved multiple times.

Some ultra high temperature ceramics have melting points above 3,900° C. These high temperature materials can also be used in concert with circulating coolant such as with regenerative cooling of rocket engines, as described here:

Ceramic Materials for Reusable Liquid Fueled Rocket Engine Combustion Devices.

Captain Steven Steel

Materials And Manufacturing Directorate

Air Force Research Laboratory

Wright-Patterson AFB, OH

http://rocket-propulsion.info/resources/articles/Ceramic_Materials_For_LPRE.pdf

Moreover, these ceramic nozzles and engine components can greatly reduce the engine weight:

Sustainable Energy

A More Efficient Jet Engine Is Made from Lighter Parts, Some 3-D Printed.

Composite and 3-D-printed components will mean jet engines that use 15 percent less fuel.

by Kevin Bullis May 14, 2013

In the LEAP engine, the ceramic matrix composites will replace only some of the nickel alloy parts. But in the future, they could be used for more engine parts, further reducing losses from cooling. This change could also allow engines to run at higher temperatures, making it possible to get more thrust from a given amount of fuel. Furthermore, composites could make engines lighter—parts made from these materials weigh one-third as much as the equivalent nickel alloy parts.https://www.technologyreview.com/s/514656/a-more-efficient-jet-engine-is-made-from-lighter-parts-some-3-d-printed/

Improvement in lift-off thrust using altitude compensation.

Altitude compensation is most known for its ability to allow sea level engines to have higher Isp and thrust under vacuum and near vacuum conditions. However, it is notable it can also allow improved Isp and thrust at sea level.

The reason is, as mentioned before, sea level engines are commonly overexpanded to improve their performance in vacuum. This however reduces their performance at sea level. This reduction is quantified by the formula:

F = q × Ve + (Pe - Pa) × Ae

where F = Thrust

q = Propellant mass flow rate

Ve = Velocity of exhaust gases

Pe = Pressure at nozzle exit

Pa = Ambient pressure

Ae = Area of nozzle exit

http://www.braeunig.us/space/sup1.htm

We estimated above using the NASA online calculator the exit pressure of the usual sea level Raptor as 1/2 bar, 50,000 Pascals(Pa). The diameter is 1.3 m for the sea level Raptor. Then the thrust loss at sea level is (50,000-100,000) × π × (1.3/2)2 = 66,400 N, 6,760 kilogram-force, about 4% of the sea level thrust of 1,700 kN.

Or said another way, using an altitude compensating nozzle can increase the sea level thrust 4%. As the altitude increases, the difference will reduce until the rocket reaches the current nozzles designed set altitude. However, thereafter the improvement in thrust and ISP will again increase until it reaches the max 7% vacuum improvement.

Bob Clark